London has given me some remarkable experiences. The Olympic Opening Ceremony springs to mind. As does one memorable morning on the Thames. And recently, London served up an episode so astonishing that it left Piran and I sitting in a pub three hours later, staring into our pints, shaking our heads, and occasionally giggling in disbelief.

As one does, Piran had put some old stone carving tools up for sale on eBay and ended up meeting a lovely guy named Tim, who turned out to know a great deal about chisels. This was because Tim is not merely a trained mason (already off-the-scale cool) but also employed as a stone mason at St. Paul's Cathedral.

I am completely delighted at the thought that: 1. There are still people who train to become stone masons and 2. Places like St. Paul's and other cathedrals have such people on staff. So when Piran revealed Tim had offered a "behind-the-scenes tour of stone masoning and bits and bobs" at St. Paul's and asked if I was interested, I think any Astute Go Stay Work Play Live Reader can guess that my answer was "Yes, yes, a thousand times yes!"

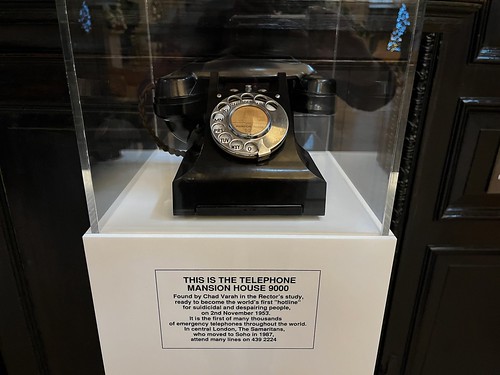

I've already blogged about St. Paul's Cathedral. But this visit to St. Paul's was... well, you'll see. Tim met us outside the main steps but quickly ushered us to an underground back entrance where we signed in and got special visitor's passes. Tim then employed his impressive set of skeleton keys to whisk us through a "Staff Only" door into the crypt and straight to a previously unknown-to-me lift up to the triforium level without climbing the 141 steps involved in the public tour.

The triforium is the area above the side aisles of a church, and though I've toured St. Paul's triforium before, this was much better. For one thing, it was just me and Piran and Tim. There was no timeline, no badge-wielding tour guide on a schedule, and, best of all, no irritating other people. And Tim seemed to be in no hurry (it was his afternoon off) all the while providing an unscripted, sometimes slightly acerbic, and completely absorbing commentary on the cathedral, the stonework that's everywhere, and stone masonry in general.

We also got into the Trophy Room, which houses Wren's famous Great Model. Oddly, this is not actually the design that was used in the end, and there are no good records that indicate exactly why it was rejected, despite having taken ten months to design and a year of master carpentering to build.

After the library and the Great Model, we paused briefly at the top of the Geometric staircase, and then proceeded to the north side of the triforium, past the large west gallery window. This is the spot where they stuff a gigantic Christmas Tree though a small bit of the window and set it up on the outer balcony-ish level every year. The tree itself is hoisted up from a point in the ceiling of the cathedral where we could just see a heavy hook dangling from what must have been a chain motor in the roof.

A little further along the magic keys were produced again and we popped out onto the trumpeter's gallery. Which is exactly what it says on the tin - the place where trumpeters stand to blow fanfares when the monarch arrives, or for whatever other thing might require a fanfare. (The Changing of the Pulpits, perhaps?) There we could look down at the public in the nave of the church.

Then it was on to the collections room, a dusty assemblage of old models, plaster bits, signage, and of course more random bits of stone. As Tim rightly said, "This is just genuinely full of interesting things."

This is the point when things got even cooler. (Hard to believe, I know, but brace yourself, it gets so so so much better.) Once again the keys came out and we started to make our way through a long series of narrow corridors and stairways sandwiched between the inside and outside walls of the cathedral.

After many winding corridors and tiny doors and low hanging beams, we finally popped out on the roof. Of St. Paul's Cathedral. The freaking roof.

Here we got to see the sort of work Tim does, because besides helping put up the Christmas Tree, one of his main things is making new stone balusters to fit into the balustrade that runs around the roof.

The balusters are made from Portland Stone, and each one is carved by hand from a template taken from the original work. Then they're craned up to the roof and carried by hand (which takes two guys) to be fitted into place. Other than the electrically winched crane it's all impressively analog.

More interesting than the view in this photograph is the evidence of major erosion shown. Those wide horizontal stones sitting on top of the balusters were laid about 300 years ago, and the seams between filled with molten lead.

After hanging out on the roof for a bit, we went back inside to more backstage-iness, this time directly above the nave of the Cathedral, where we could see the tops of the domes that make up the ceiling.

Other than the overall amazingness of the tour in general, one of the best things was being in that big stone building and learning about the stone itself. So many of London's great buildings are made of stone, but the stone itself never gets much attention. For instance, up above the nave, we looked at an unassuming corner of stonework along the wall.

We also got to pop out into the famous Whispering gallery, closed to the public since 2019. They're currently getting ready to install safety fencing, and doing other renovation work on the gallery before it reopens. And of course one of the things being renovated is the stone floor.

Our last stop might have been my favourite of the day - the mason's workshop back in the modern car-park-ish area where we entered. (I take that back. Of course my favourite was the roof, but I love a functioning workshop. Love, love, love.)

The Mason's Workshop at St. Paul's was not big or grand. But it was well-kept and well-lit and appropriately dusty and just excellent. I mean look at this tool cabinet!

In looking at this shape it seemed obvious to me that you'd start with a rectangular block and rough-saw the basic shape, then chisel out the detail. But of course that's not how they do it. Yes, they start with a big rectangular blank, but from there the whole thing is chiselled by hand. Every chip. By hand. Chip. Chip. Chip. Chip. Chip. The first one took Tim three weeks, though he's faster now. And he calculated that if you chisel for a whole eight hour work day with an average hammer, that's eight tons of weight wielded by your hammering arm. Apparently that can net you an impressive six pack on one side. A three-pack, shall we say?

We hung around in Tim's workshop for quite a while, and he showed us a bit of mason-ing, which looks just like you'd expect. Guy with a hammer and chisel chipping off tiny bits of stone over and over and over again. Impressive, repetitive, and really, really... old. You get the impression you could transport Tim back to the 17th century stone yard where they cut the original blocks for St. Paul's and he could pick up a hammer and chisel and fit right in with the rest of the gang, except for his modern steel-toed boots.

We tried to persuade Tim to let us buy him 100 pints at the nearest pub as thanks for the most amazing afternoon, but he had other plans. So Piran and I wandered off to slake our own parched throats and sit in disbelief.

In the immortal words of John Denver: "Some days are diamonds, some days are stone".

But the best days are both.